Overhead conveyors are widespread as the main conveying device of modern plants. Overhead conveyors are designed for transportation of parts and assemblies to the place of assembly or to the painting department. The advantage of overhead conveyors is the spatiality of the route, accessibility to the product from all sides, saving production space. The overhead conveyor track is made in the form of a monorail fixed at a certain height. The overhead conveyor consists of a traction element with brackets permanently attached to it, to which the load-bearing (working) elements in the form of hangers are attached. The brackets move on a closed track by means of a chain. The traction element is driven by a drive mechanism consisting of a gearbox with a sprocket or a tracked chain. In industrial areas, these types of conveyors have the designation PNTs-80, PNTs-100, PNTs-160, as well as GN-80, GN-100, and GN-160. Scope of application: painting lines, batch, and high-volume production plants, warehouses of finished products, machine factories, refrigeration, and meat-processing plants, etc.

Drive elements for overhead conveyors

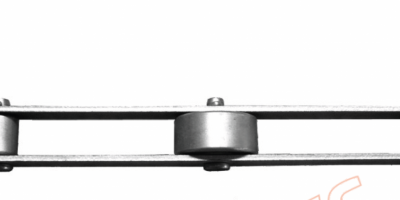

Chains for painting line

Crawler drive chains

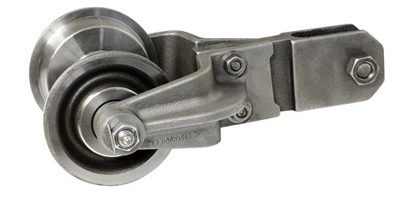

Brackets for overhead conveyors

Forged traction collapsible chains of domestic and European series